Electrospray-enabled Langmuir-Blodgett assembly

We solve a longstanding problem in Langmuir-Blodgett assembly using electrospray-assisted spreading. It greatly broadens the scope of this technique and makes it more standardizable .

Langmuir-Blodgett (LB) assembly has been routinely used in research labs for nearly a century for preparing molecular and colloidal monolayers. In the historical video below, Katherine Blodgett herself talks about her innovation of “invisible glass” with anti-reflective molecular thin films .

When extends to colloidal nanomaterials, LB assembly has been used to create close packed monolayers of various types of nanoparticles, nanorods, nanowires, nanotubes and 2D nanomaterials. However, the need for volatile, water-immiscible solvents to spread the colloids on water has always been a “pain”, in terms of colloidal stability, processability and chemical safety, making scaled up applications difficult.

LB colloidal assembly

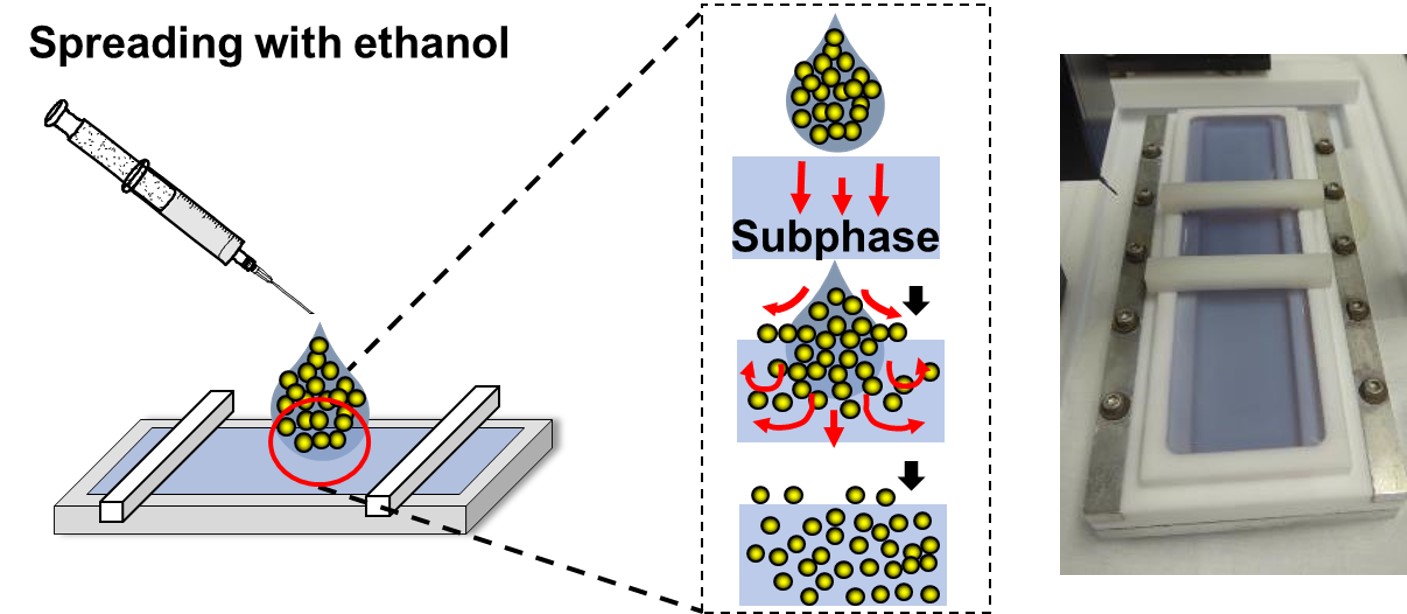

Using water-miscible spreading solvents would avoid all of these problems, but it tends to lose most materials to water subphase due to intermixing (see below for an example of spreading Au nanoparticles on water using ethanol). This makes water-miscible spreading solvents ineffective, and hard to standardize or reproducible for LB colloidal assembly.

Water-miscible spreading solvent results in significant intermixing

This dilemma can be solved by electrospray spreading, in which the small volume of the microdroplets is readily depleted during initial spreading, leaving no extra solvent for mixing (see below for a video showing electrospray spreading of Au nanoparticles from ethanol on water). As is demonstrated with several prototypical colloidal systems, electrospray allows high-yield, high-throughput spreading of colloidal materials on water surface using environmentally benign, water-miscible solvents (even water itself), which liberates this century-old technique from many constrains related to material processing and significantly expands its scope.

Electrospray apparatus can be automated and fully integrated with existing LB systems, which should help to standardize this technique and scale it up from LB assembly to LB manufacturing.